SHEET METAL TRANSFORMATION

Do you have a complex, large-scale project in the works?

The art of quality sheet metal transformation is all about precision and attention to detail. Beauchemin Industrial experts understand your requirements and the importance of ensuring precision throughout the manufacturing process. We are a recognized benchmark in quality execution, and are known for our leading-edge expertise in many fields of activity. Our extensive experience has allowed us to develop the best techniques for a wide variety of metals that include:

Steel | Aluminum | Stainless steel | Galvanized steel

SHEET METAL TRANSFORMATION SERVICES

-

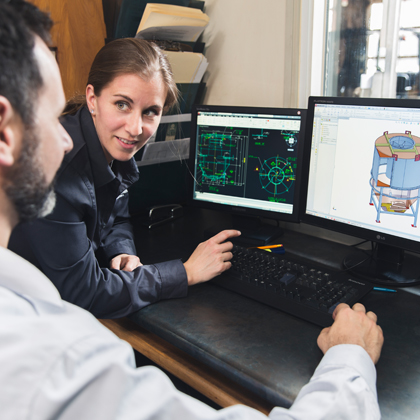

PLANS IN 2D OR 3D

Thanks to a close collaboration between you, your engineering firm, our technical drafting department and our experts in sheet metal transformation, your final product is guaranteed to be of the finest quality and in keeping with your precise requirements.

Software used:

- AutoCAD

- SolidWorks

-

ROLLING, CUTTING, FOLDING AND BENDING

All operations are conducted with precision in mind

Our workshop, which includes two work areas, one of which has a height clearance of 23 feet, allows us to accommodate large-scale parts. And our equipment is designed to handle rolling, hydraulic cutting, folding and bending of 22-guage to 3/8-inch sheet metal in steel, stainless steel and aluminum.

Our equipment included among other things:

- hydraulic shear, 1/4 × 120 inches

- hand lever shears

- 4-metre wide (250-tons)

- 5-axis CNC press brake machine

- 160-tons, 144-inches hydraulic press brake

- manual bending machine

- wide variety of punches and dies for many type of bending

- swaging machine

- plate and sheet roll (8, 4 and 3 foot )

- automatic section bender – 3 rollers

- lockformer

- ironworker machine

- notcher

- several bridge cranes, including two with 10-tonne capacity for a total of 20 tons

-

FINISHING AND PAINTING

Take advantage of our impeccable turnkey service

All custom-made parts and industrial equipment manufactured for you can be painted in-house. We have a 725 sq. ft. painting workshop with 12.5-foot ceilings that can accommodate large-scale projects. And we can prepare surfaces according to SSPC standards before applying liquid paint.

Beauchemin Industrial turnkey services

- Liquid painting

- Pickling

- Passivation

- Insulation and cladding

For other finishing requirements such as powder coating or galvanization, and to offer you a complete range of turnkey services, we partner with a network of suppliers who share our concern for quality and customer satisfaction.

Finishing services ensured by our partners

- Galvanization

- Heat treatment

- Powder coating

-

PACKING AND SHIPPING

Safe delivery for your industrial equipment

Beauchemin Industrial ensures your industrial equipment is always delivered in the best possible manner. We take great care in packing it with the proper materials and offer our support in planning delivery of your project, whether it’s by truck, train or ship.

Interested in our sheet metal transformation services?

We’ve put together a gallery of several sheet metal transformation projects we have successfully completed.